The intention to reduce waste is often genuine and from a position of a) wanting to reduce impact on the environment, and/or b) wanting to reduce costs.

Both scenarios offer a path to reducing food waste in the kitchen and can contribute to a collective movement of chefs around the world who are striving to be leaders in their own ecosystems, but also, as ambassadors of a more sustainable model of foodservice.

In the pursuit for a low food waste ethos the “whack-a-mole” approach can appear. Chefs and cooks are constantly chasing their tails within their existing system, trying to eliminate the food waste that has accumulated through their regular operations by running specials, making elaborate staff meals and stockpiling items in the freezer for a time when they may realize their value. Enthusiasm can be quickly lost when the realisation of the associated workload is taken into account.

This method seems akin to converting a combustion car to electric, while still needing to drive the car every day. It is a huge challenge and one that restaurants often don’t have the resources to expend on an ongoing basis.

But what about if low waste was built into the design. A system with baked-in resilience, closing the loop on the waste streams found in each and every dish.

Low waste high-end restaurants often use fermentation to manage their waste streams and coax flavour from the most unassuming of byproducts. This is an incredible way to create unique flavours while dealing with surplus that may be discarded. But what if you’re a chef making from-scratch pub food? Or a diner, sandwich shop or a smash burger spot? I strongly believe there is still a way.

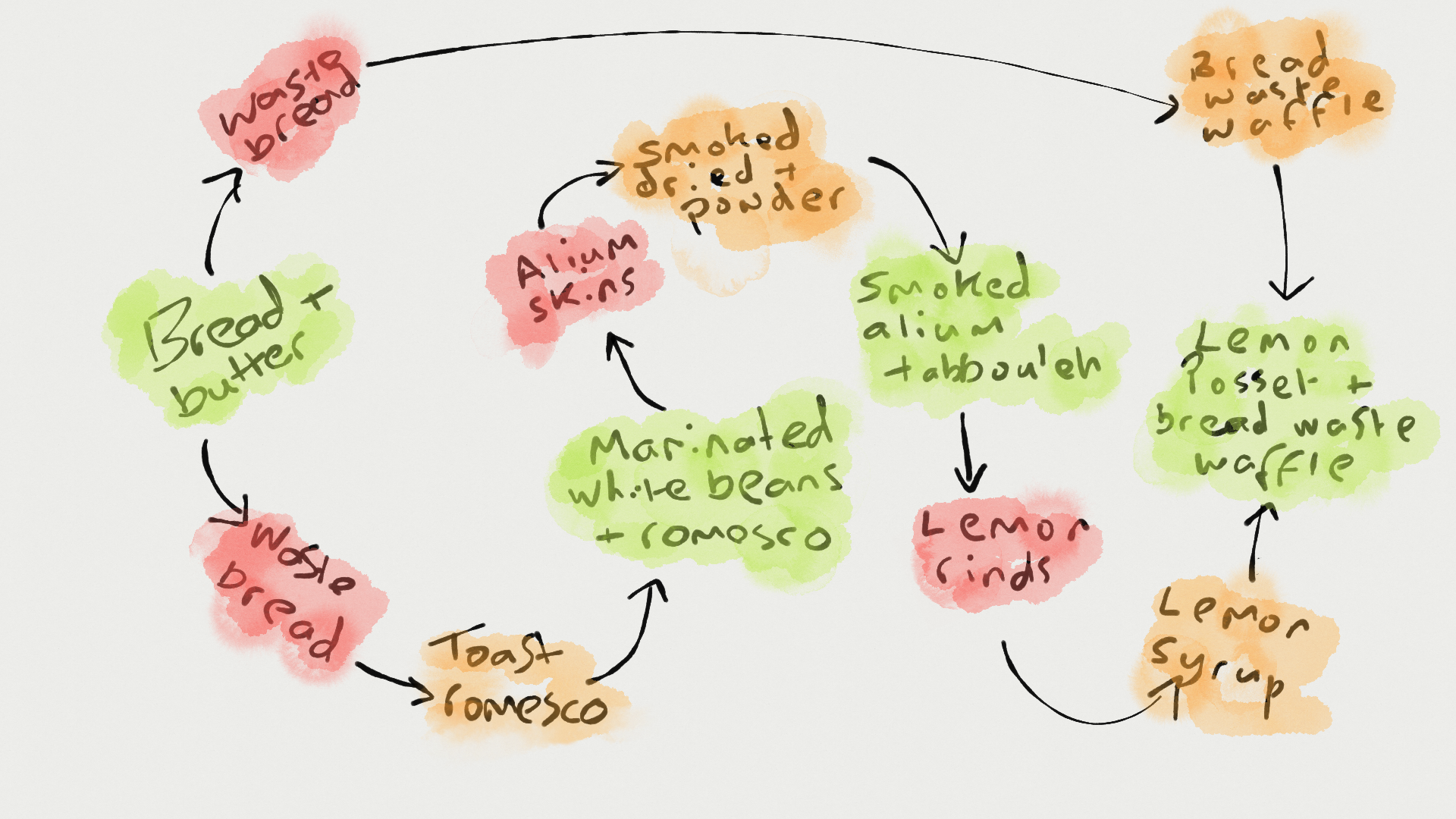

Green: Dish

Red: “Waste” Item/New Ingredient

Orange: Dish Element

By highlighting the expected waste streams from each dish, a map can be made before the waste is created. Imagine a roadmap that gives purpose to the things that would otherwise be discarded, to see them as ingredients with a given purpose rather than a problem that needs to be constantly dealt with. This process can be done when ideating new menu items, R&D and dish costing. Identifying how those “waste” items can become ingredients for other dishes allows the loop to be closed on that dish.

Some other benefits include:

-

Staff learning to cook with a closed loop mindset

-

Lower food cost

-

Owning a library of ingredients unique to place

-

Lower carbon cost

-

Lessened extractive impact on the environment

So when building your next menu or dish, make a list of the expected by-products of prepping and serving each plate of food and how those items can be re-labelled as ‘ingredients’ to be used elsewhere in the menu. With this mindset, we can achieve a model of efficiency, akin to the systems of nature, where everything has a use, a purpose and adds value to the ecosystem.